Modern cars contain many sensors and control units. Our homes have “smart” appliances. Portable devices can check our blood sugar or blood pressure. Phones and other communication tools are now deeply integrated into everyday life.

As these devices become more advanced, the components inside them continue to shrink. The smaller a component is, the more sensitive it becomes to electrostatic discharge (ESD). This means that even a tiny static discharge — one we might not even notice — can damage an expensive chip.

For this reason, manufacturers need to consider ESD protection already in the design stage, as both quality and reliability depend on it.

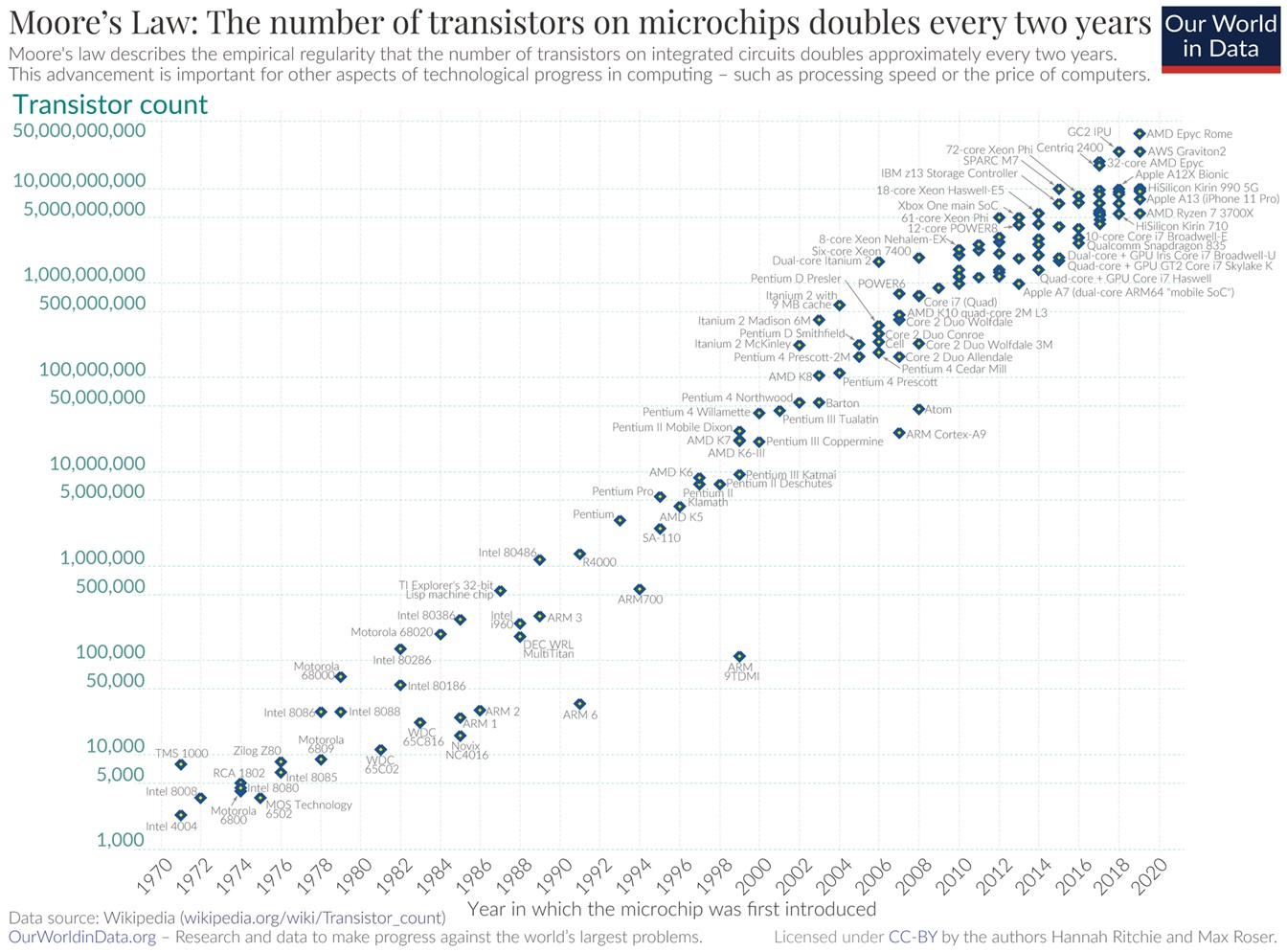

Moore’s law and ESD

Licensed under CC-BY by the authors Hannah Ritchie and

Max Roser

Back in the 1960s, Gordon Moore1 noticed that the number of transistors in computer chips roughly doubled every two years, while the parts kept getting smaller. Because of this, modern circuits are very sensitive to ESD.

The vulnerability of the latest technologiesChips made with 5 or even 3 nanometers technology have extremely thin wires and special materials. This means that even a tiny discharge can damage them. Especially vulnerable are: |

|

The hidden danger: latent ESD damage

Why is it worth investing in ESD protection?

For electronics manufacturers, ESD protection should not be seen as an unnecessary expense, but as an investment that delivers a return.

With effective protection in place, manufacturers can achieve:

• Lower scrap rates during production

• More reliable products with longer lifespans

• Reduced warranty and repair costs

• Fewer product recalls

• Better-controlled and more efficient manufacturing processes

• Higher and more consistent product quality

Gábor Lovász, Ph.D.

|

Technical information |

Reference literature

- Cramming more components onto integrated circuits, reprinted from Electronics, Volume 38, Number 8, April 19, 1965, pp.114 ff.

- Roser, M., Ritchie, H., & Mathieu, E. What is Moore's Law?. Our World in Data. 2023.03.28. Available: https://ourworldindata.org/moores-law

![]()

I would ask for help regarding ESD protection |

Magyar

Magyar English

English